AUTOMATED PROCESSES WITH KOCH PAC-SYSTEME

Drawing on decades of experience, KOCH engineers have been investing their expertise in evaluating, developing and implementing semi-automatic and fully automated lines in countless variants. Customer-specific requirements are configured in close cooperation with the users from a broad range of automation options.

Regardless of the control platform, all machines are visualized and operated with a RedDot award-winning web-enabled user interface.

Whether for marking packaging, for control and inspection systems, or feeding and handling systems, at KOCH you will find a broad range of options with field-proven solutions for your automated processes.

1

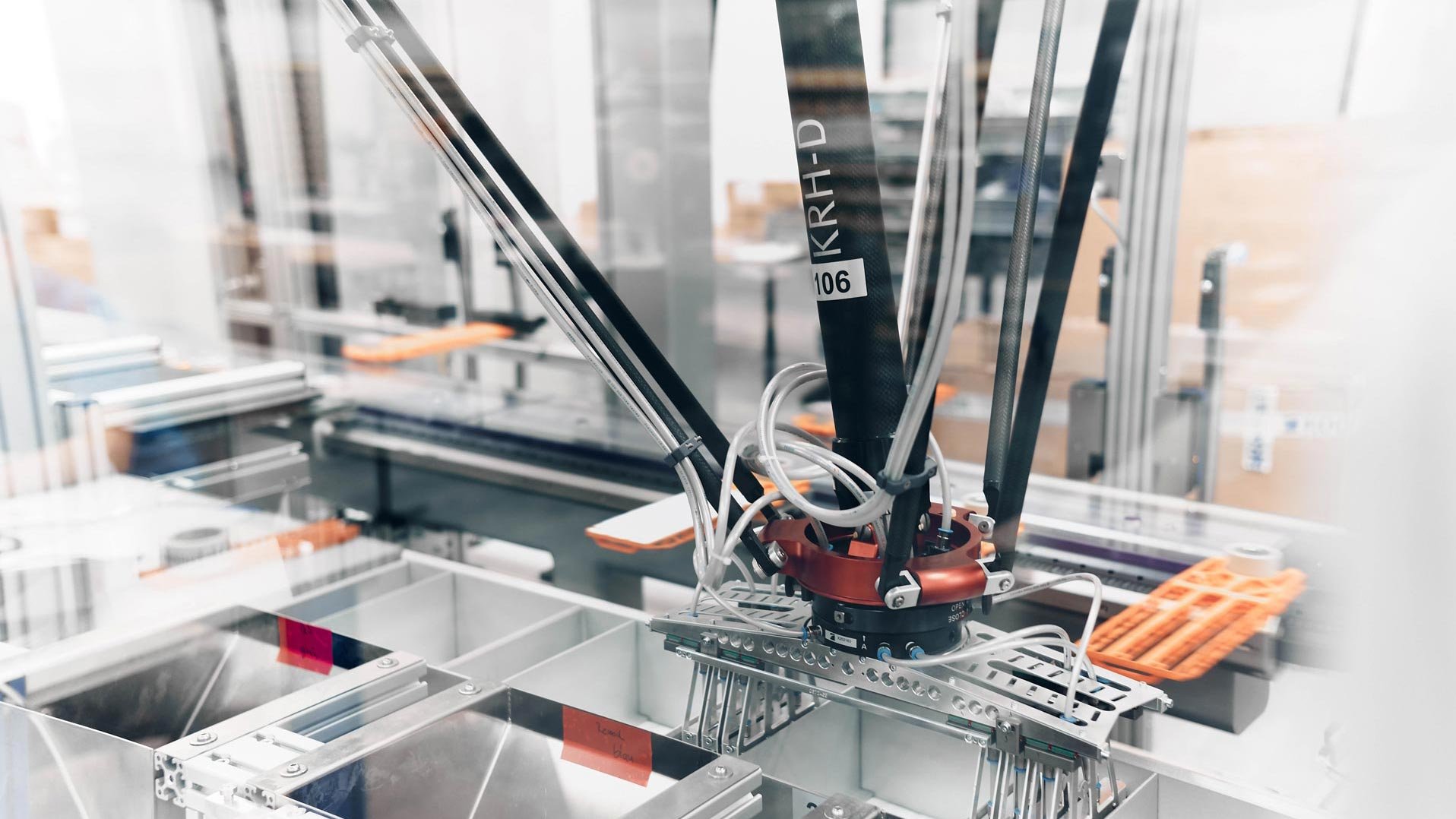

FEEDING & HANDLING SYSTEMS

Small or big batches – no problem for KOCH! We evaluate your requirements and design the right feeding and handling concept for you. From bulk goods to separating. From accumulation to grouping. Our robotics expertise covers multiple established brands and kinematic solutions. Our own KOCH KRH-D Delta Robot system excels on the market with a wide variety of solutions.

3

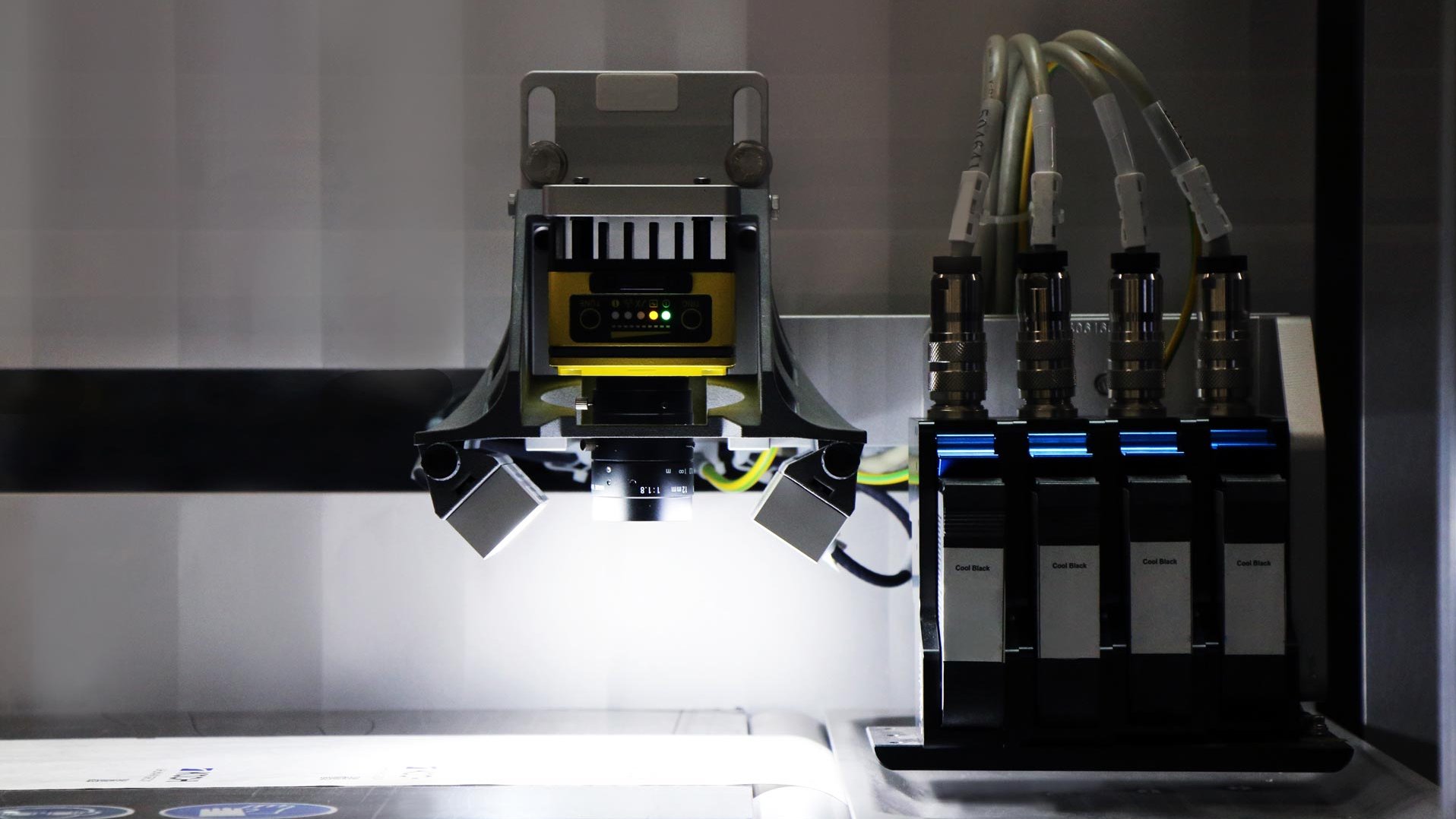

CONTROL & INSPECTION SYSTEMS

Complete quality control during the packaging process – even at high speeds; that’s the excellence you can expect from our control and inspection systems: Process sensors, integrated weight control, code readers for all commercially available codes (1D & 2D) and vision systems (b/w & color) check product, print content and position.