Custom blister machines and cartoners as well as integrated packaging lines for consumer goods from car parts to toothbrushes – starting with a batch size of one.FIND OUT MORE

Since 1969, KOCH Pac-Systeme has built up an outstanding reputation around the globe as a manufacturer of blister machines, cartoners and packaging lines. All of our packaging technologies feature a modular design, which allows them to provide custom solutions for specific requirements in the areas of consumer goods, healthcare products and contact lenses.

POWERFUL TECHNOLOGY THROUGH PACKAGING MACHINES DIRECTLY FROM THE MANUFACTURER

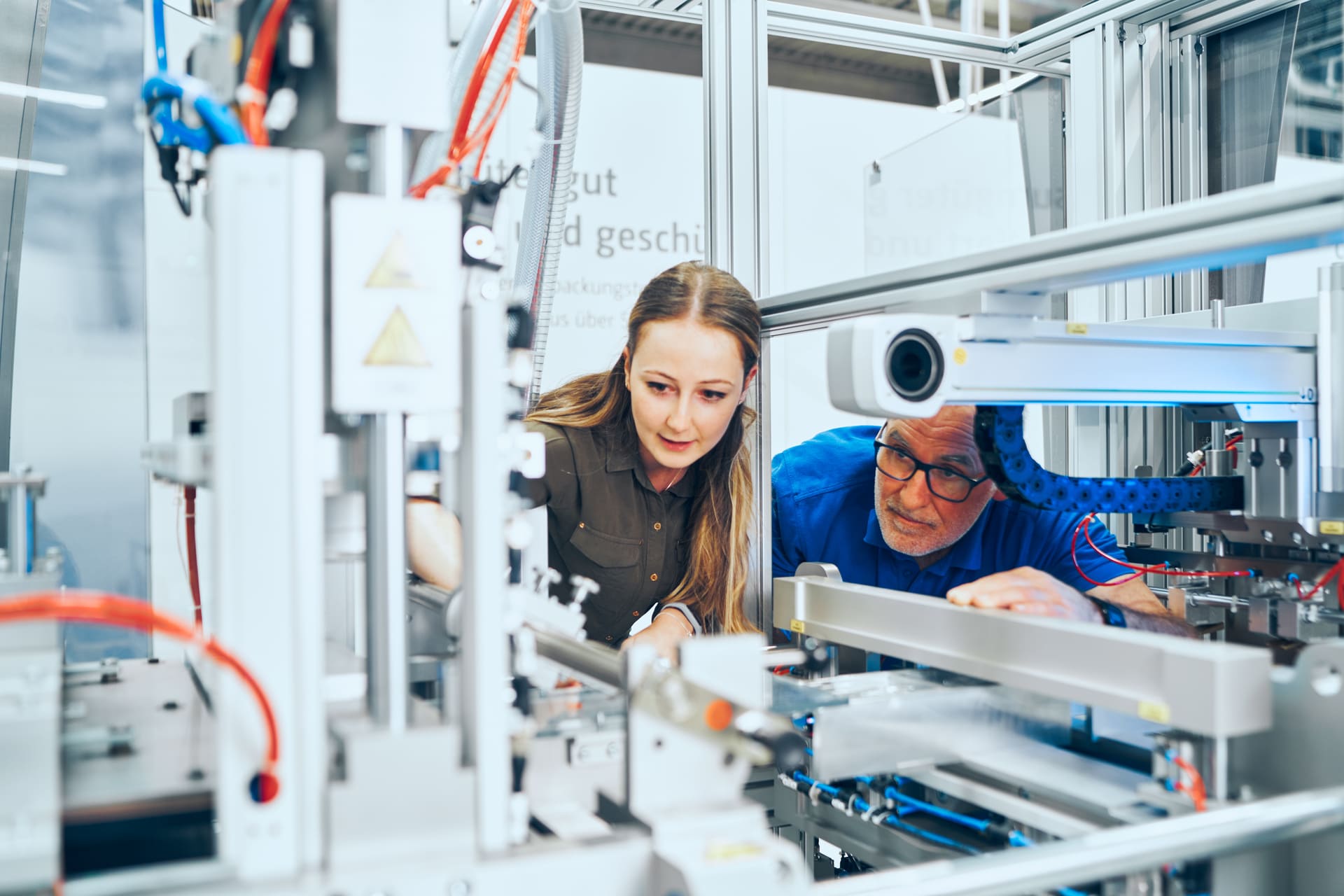

KOCH Pac-Systeme stands for the highest quality and most efficient custom packaging solutions. For over 50 years, we have impressed customers at home and overseas with the quality of our products like blister machines and packaging lines as well as our services, our expertise and the commitment of our employees.

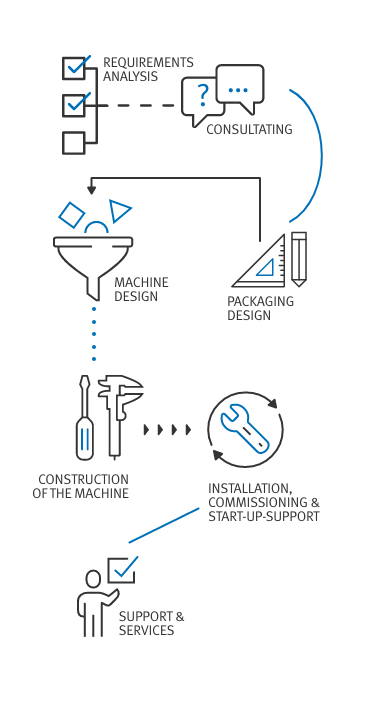

To design your optimal blister packaging solution, KOCH experts will support you throughout the entire design process all the way to the commissioning of your system on site. Comprehensive services and technical support allow the efficient operation of your custom packaging machine or packaging line.

Whether it's a pen or a brake disc, medical implants or pharmaceutical products, monthly lenses or eye drops. Regardless of which product from the consumer goods, Healthcare or contact lens sectors you want to package, KOCH Pac-Systeme definitely has the right blister machines, cartoners and integrated packaging lines to meet your needs.

When they need efficiency, quality and reliability, well-known manufacturers from around the globe rely on packaging technologies by the manufacturer KOCH for their mass production, the manufacture of high-quality products or even their small series down to a batch size of one.

Thanks to their modular design, KOCH blister machines, cartoners and packaging lines are put together according to your specifications. All primary and secondary packaging process steps are fully automated. Required inspections as well as labeling with fixed and variable data are performed without disrupting the process.

That is how we design custom packaging solutions according to your specifications. Economically and sustainably.

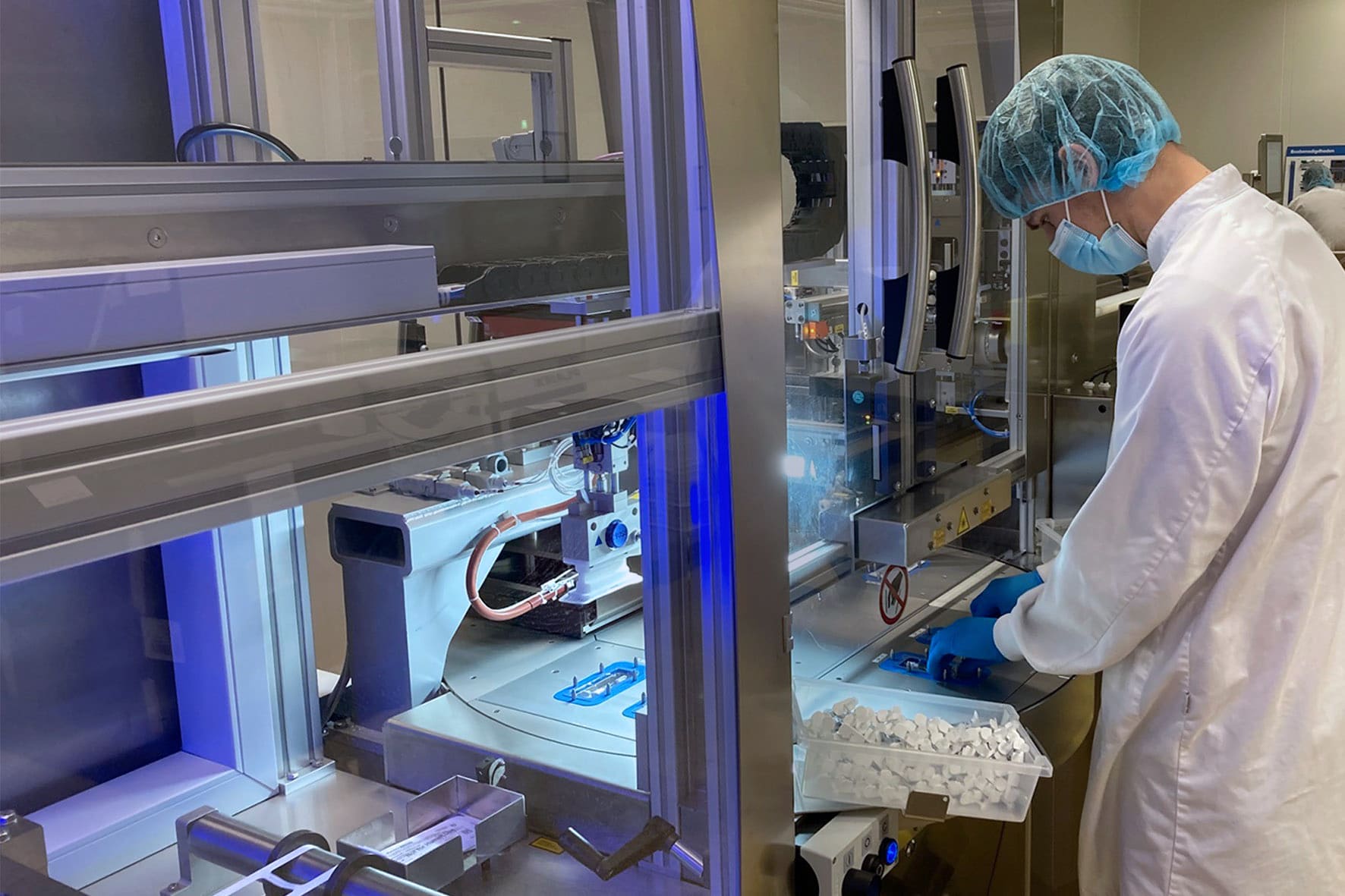

HEALTHCARE

Custom blister machines for packaging sensitive medical and pharmaceutical products in transparent blister packaging.FIND OUT MORE

CONTACT LENSES

Custom packaging lines for the sterile and economical packaging of contact lenses and accessories.FIND OUT MORE

SERVICES

Comprehensive, modular service portfolio with which we will support you throughout the entire service life of your packaging solution.FIND OUT MORE